Tension Control

Tension variation is minimized, since the drum has a shape close to round. Additional tension device may be offered under option in case warp have to be made hard beam which is textile for industrial material.

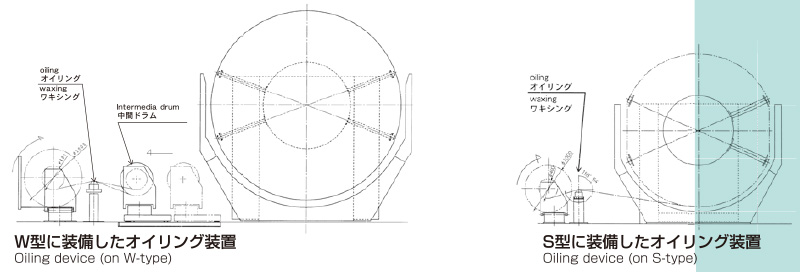

And in case beam have to be always very hard, it is advisable to choose "W" type which prewinds warp ends onto a intermediate drum before beaming.

Wound warp sheet moves precisely on electronically controlled conveyor belt on the drum, so pre-set warping width is obtained very accurately. It is absolutely not necessary to adjust warping width by the aid of intermediate drum like it was the case with absolute sample warping machine, so "S" type which beams directly from the drum is more advantageous in view of both working speed and amount of investment as long as ordinary fabrics are processed.

Oiling and waxing

Should warp yarns require oiling or waxing, such device are offered under option. In case sizing is required. The single end sizing winder should be used for warping.

For yarns tending to generate static electricity, static eliminator is provided under option.

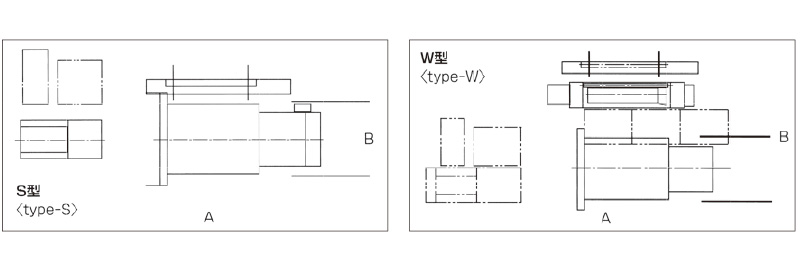

Floor space for NAS-series

| Model | Working Width |

Width A | Depth B | Height H | Required door size (for transportation) |

|---|---|---|---|---|---|

| 7m Drum Model 1407m |

2250m | S 12470 W12470 |

S 5666 W 7125 |

S 2680 W 2680 |

*2200mm(W) × 2270mm(H) |

| 2500m | S 12970 W 12970 |

S 5666 W 7125 |

S 2680 W 2680 |

*2200mm(W) × 2270mm(H) | |

| 7m Drum Model 1407m |

2250m | S 12730 W 12730 |

S 6615 W 7710 |

S 3640 W 3640 |

2250mm(W) × 2600mm(H) |

| 2500m | S 13230 W 13230 |

S 6615 W 7710 |

S 3640 W 3640 |

2200mm(W) × 2600mm(H) |

Outstanding features (Patented)

- Feeding both from stationary & Rotational creel in one process.

- Stationary creel can change color at the Maximum warping speed of 1500m/min.

- Slack yarn drawing back system.

- Wound yarn aligning system.

- Belt shift control system for different yarn count.

| NAS-140N | NAS-300N | NAS-140C | NAS-300C | |

|---|---|---|---|---|

| Drum Circumference | 7m | 10m | 7m | 10m |

| Maximum Warping Length | 420m | 600m | 420m | 600m |

| Warping Width | 2250mm(Option:250mm) | |||

| Yarn selector for Stationary creel |

10Colors | |||

| Max Warping speed with Standard creel(Max) |

1500m/min | |||

| Max Leasing speed with Stationary creel (Max) |

1500m/min | |||

| Rotational creel 8 position |

none | 8Positions | ||

| Yarn selector for Rotational creel |

none | 8Positions equipped | ||

| Warping speed with Rotational creel(Max) |

none | 1000m/min | ||

| Leasing speed with Rotational creel(Max) |

none | 1000m/min | ||

| Yarn drawing back device (Stationary creel) |

Equipped | |||

| Yarn drawing back device (Rotational creel) |

none | Equipped | ||

| Warping both from standard and Rotational in one process |

none | Equipped | ||

| Wound yarn aligning Device | Equipped | |||

| Accumulators for Hi speed warping |

Equipped | |||

| Belt shift control for Yarn count |

Option | |||

| Independent Yarn speed Setting for Stationary creel |

Option | |||

Option equipment for Beaming device.(All models)

- intermediate slide type rewind drum. (W-type)

- Oiling/Waxing device for liquid material

- Beam doffer device

- Special beamer for wide beam

Note

- Please inform us kind of yarn and density as the maximum warp length varies according to them.

- Please inform us the size of bobbins that you see as the type of creel stand is different according to your bobbin size.

| NAS-140N | NAS-300N | NAS-140C | NAS-300C | |

|---|---|---|---|---|

| Supply Voltage | AC200,380,400,415,440V 50/60Hz 3 phases (4 cables) Other Voltage on request. |

|||

| Power Consumption | 11kw | 15kw | ||

| Machine with Intermediate drum (W-Type) | ||||

| 15kw | 19kw | |||

| Supply Air | 0.7 Mpa (2.2kw) | |||

| Air Consumption | 250L / min | |||

Machine stop motion

- Stationary creel. (Equipped accumulator with stop motion)

Equipped “ELTEX” stop motion. (Slide Sensor) - Rotational creel. (Equipped accumulator with stop motion)

Equipped slide sensor and fiber sensor.