Let "ROBO-WARPER" do your precise job

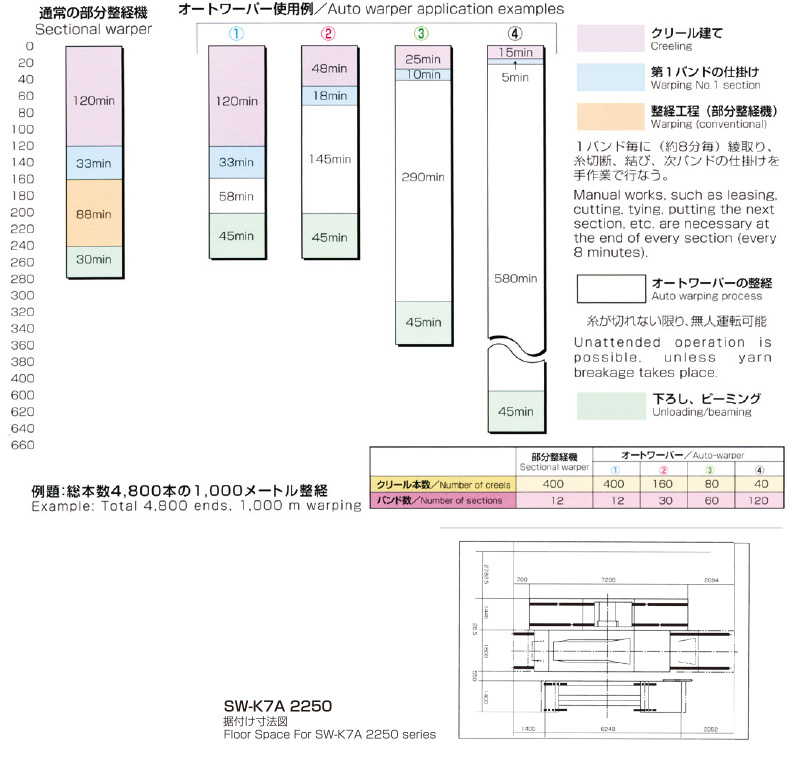

Very often, robots can perform and repeat precise jobs better that human beings. Various manual works needed on conventional sectional warper will belong to this category in view of required uniformity through the warping width.

Susuki’s automatic sectional warper "SW-K7A" is a new product range based on the automatic warping technology proven on its preceding model “SW-K5A” but with enlarged drum size. With its larger drum size, longer warp length up to 6144m may be attained, and more leasing elements may be inserted which enables you to drive the warp sheet in maximum 8 layers for the subsequent sizing process besides normal lease.

Today, work load on preparation department is increasing day by day according as processing of varied short-runs becomes daily practice. Further to cope with “quick response“, more effective warping may be possible by employment of complex machine configuration, such as dual-creel with dual leasing reed-head with “SW-K7A” automatic sectional warper.

Let us forget old good time to have produced more then thousands of meters with one style, and face up to today’s fashion trend. Suzuki offers you a new era of warp preparation.