Short warp is our profession

No matter how CGS technology has advanced, it only can visualize the color-matching of the aimed fabric, and the touch of the fabric cannot be composed artificially. There is no better way but to present a piece of actual sample cloth in order to appeal to buyer’s emotion without spending much explanation. Suzuki offers a fair possibility to cope with quick response which is the market demand of today.

No matter how CGS technology has advanced, it only can visualize the color-matching of the aimed fabric, and the touch of the fabric cannot be composed artificially. There is no better way but to present a piece of actual sample cloth in order to appeal to buyer’s emotion without spending much explanation. Suzuki offers a fair possibility to cope with quick response which is the market demand of today.

No matter whether fashion- or industrial fabric it may be, Suzuki offers appropriate warping technology for sample fabric with you can appeal to buyers, and at the same time, the weavability can be verified in advance in advance.

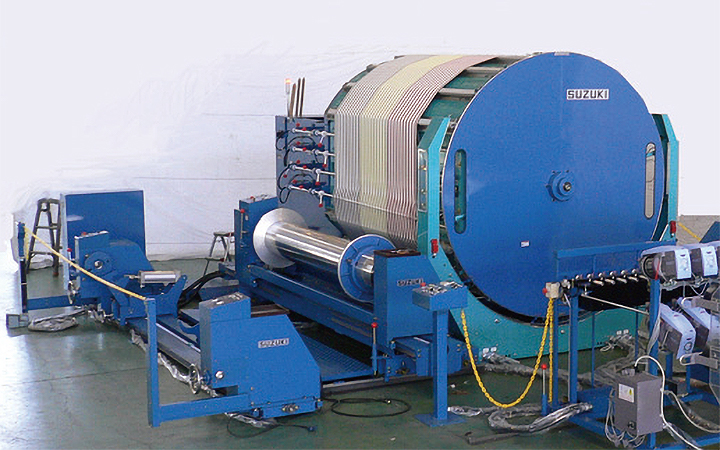

Real production of short-runs

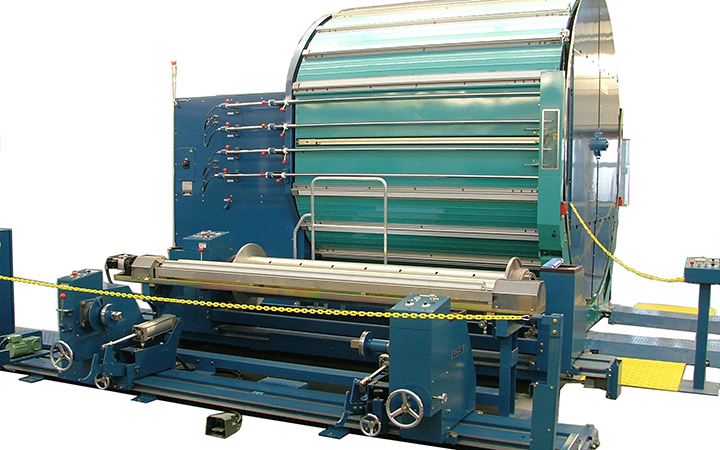

Diversified customer’s taste today forces you to produce short-runs less than a few hundred yards. Yet, you have to go on the same procedure, dividing bobbins, putting them onto creels, leasing at the end of each section, cutting the section and tying it onto the neighboring band as long as the traditional sectional warper is employed. Suzuki’s fully automated warp sampling machine “NAS” series and auto-warper “K7A” contribute to eliminate manual work, hence enable you to assume orders of short-runs without hesitation.

Diversified customer’s taste today forces you to produce short-runs less than a few hundred yards. Yet, you have to go on the same procedure, dividing bobbins, putting them onto creels, leasing at the end of each section, cutting the section and tying it onto the neighboring band as long as the traditional sectional warper is employed. Suzuki’s fully automated warp sampling machine “NAS” series and auto-warper “K7A” contribute to eliminate manual work, hence enable you to assume orders of short-runs without hesitation.

Once all preparation has been done, the machine carries out the job without human intervention, so it is possible that the operator does some other tasks within easy access of the machine until he is needed for unloading upon completion of the warping, or he takes care of more than one warper.

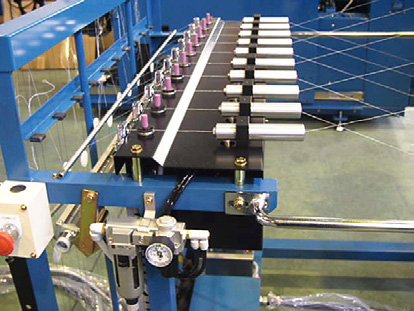

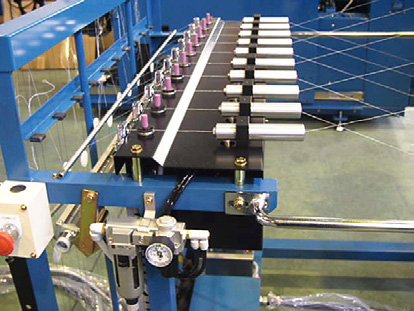

Loose yarn draw back system

With the aid of newly developed “Hi speed selector” to draw back loose end which had been presented until new color is selected, by mean of air jet nozzle, warping time of colorful stripes with standard creel has substantially been shortened. Accumulators to be adapted here have a capacity of 1500m/min.

With the aid of newly developed “Hi speed selector” to draw back loose end which had been presented until new color is selected, by mean of air jet nozzle, warping time of colorful stripes with standard creel has substantially been shortened. Accumulators to be adapted here have a capacity of 1500m/min.

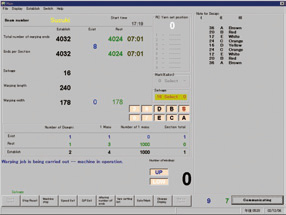

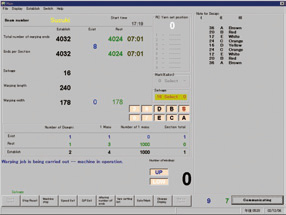

Operation display on window (P/C)

Besides the pattern design, you only have to input warping width, total number of ends and density . put up bobbins and push start-button to let the machine carry out designated warping job. And the existing saved design pattern date is able to back-up into other media which active on Windows and of course it is possible to transfer the design date to Machine P/C from Host P/C by run network connection.

Besides the pattern design, you only have to input warping width, total number of ends and density . put up bobbins and push start-button to let the machine carry out designated warping job. And the existing saved design pattern date is able to back-up into other media which active on Windows and of course it is possible to transfer the design date to Machine P/C from Host P/C by run network connection.

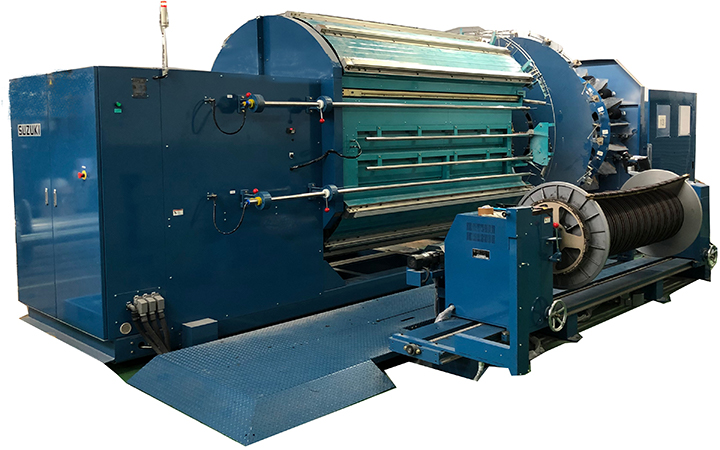

Belt shift control

New machine can makes mixed yarn count stripe. The Machine can control the belt shift speed according with yarn count setting for making flat surface onto warp drum by wound yarns.

New machine can makes mixed yarn count stripe. The Machine can control the belt shift speed according with yarn count setting for making flat surface onto warp drum by wound yarns.

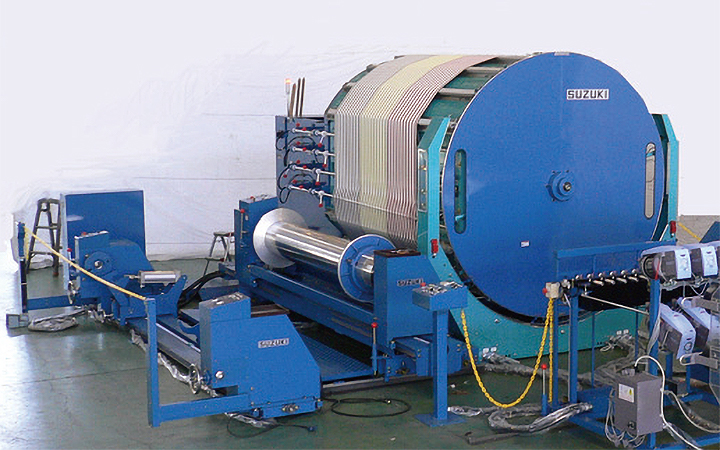

Rotational creel for High speed Warping

It is often pointed out that single-end warping takes too long time in case of plain – and / or chambrais like fabrics in compensation for not requiring to divide bobbins into small packages. Rotational creel (option) is an answer for such cases. Warping time for plain or short repeat pattern below 8 ends can be substantially shortened, since 8 yarns are wound simultaneously.

It is often pointed out that single-end warping takes too long time in case of plain – and / or chambrais like fabrics in compensation for not requiring to divide bobbins into small packages. Rotational creel (option) is an answer for such cases. Warping time for plain or short repeat pattern below 8 ends can be substantially shortened, since 8 yarns are wound simultaneously.

Accumulators can alter the rotational direction depending on S/Z twist. Highly twisted yarns can be processed without losing twisting effect, and the unwinding processed can be carried out without entanglement of neighboring yarns.

No matter how CGS technology has advanced, it only can visualize the color-matching of the aimed fabric, and the touch of the fabric cannot be composed artificially. There is no better way but to present a piece of actual sample cloth in order to appeal to buyer’s emotion without spending much explanation. Suzuki offers a fair possibility to cope with quick response which is the market demand of today.

No matter how CGS technology has advanced, it only can visualize the color-matching of the aimed fabric, and the touch of the fabric cannot be composed artificially. There is no better way but to present a piece of actual sample cloth in order to appeal to buyer’s emotion without spending much explanation. Suzuki offers a fair possibility to cope with quick response which is the market demand of today.  Diversified customer’s taste today forces you to produce short-runs less than a few hundred yards. Yet, you have to go on the same procedure, dividing bobbins, putting them onto creels, leasing at the end of each section, cutting the section and tying it onto the neighboring band as long as the traditional sectional warper is employed. Suzuki’s fully automated warp sampling machine “NAS” series and auto-warper “K7A” contribute to eliminate manual work, hence enable you to assume orders of short-runs without hesitation.

Diversified customer’s taste today forces you to produce short-runs less than a few hundred yards. Yet, you have to go on the same procedure, dividing bobbins, putting them onto creels, leasing at the end of each section, cutting the section and tying it onto the neighboring band as long as the traditional sectional warper is employed. Suzuki’s fully automated warp sampling machine “NAS” series and auto-warper “K7A” contribute to eliminate manual work, hence enable you to assume orders of short-runs without hesitation.